Changes in the Physicochemical Characteristics of Sancho Oil according to the Purification Process

© The Korean Society of Medicinal Crop Science. All rights reserved.

This is an Open-Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License ( http://creativecommons.org/licenses/by-nc/3.0 ) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Sancho oil extracted from Zanthoxylum schinifolium (Siebold & Zucc) is a useful edible oil that has been in use for a long time, but it is known to be susceptible to rancidity. Sancho oil purification can remove impurities to prevent rancidity. This study was performed in order to improve the quality of sancho oil and enhance its availability throughout the purification process.

Sancho oil extracted in Hadong, Korea was refined via the degumming and deoxygenation processes, following which we examined the changes in the polyphenol content, fatty acid content and antioxidant activity of the oil. Acetic acid was effective for deoxygenation of sancho oil and 2 N NaOH was effective for its deoxidation. The polyphenol content and antioxidant activity were reduced by the purification process. Saturated fatty acids contents did not vary with the degumming and deoxygenation processes, however the content of unsaturated fatty acids were slightly reduced.

This study suggests that the process of sancho oil purification used in this study will contribute to the increased use and storage of sancho oil.

Keywords:

Zanthoxylum schinifolium Siebold & Zucc, Degumming, Deoxygenation, Total Polyphenol ContentINTRODUCTION

There has been an increased interest in the health benefits of vegetable oils such as its anti-ageing function (Youn et al., 2006). Edible oils and fats as well as processed products which properly minimize the damage that can be caused by oxidative stress, may tend to experience increase in their consumption (Anderson, 1999; Gutteridge and Halliwell, 1994). The supply of edible oils in Korea is very low compared to the demand as its availability relies on importations, which are usually not in sufficient quantities. At present, edible oils used for food preparation are mainly extracted from crops. However, the study of functional vegetable oils is limited to some plants such as peach seed and apricot kernel oil (Park et al., 1984), Pinus koraiensis oil (Kim and Yoon, 1975), evening primrose seed oil (Pyo et al., 1989), with limited research conducted on sancho oil.

Sancho (Zanthoxylum schinifolium Siebold & Zucc.) mostly grows in the mountain areas, with about 200 species of the plant distributed worldwide. The leaves, bark and fruits of Sancho tree could be used to obtain sour, vegetable oil and essential oil. Sancho has been used as a directional stomach, anti-inflammatory, as well as in diuretic, such as preservatives and anti-parasitic. In addition, it has been used during detoxification, for toothache and neuralgia, and in a wide variety of applications for private use during poor circulation, colds, cure for paralysis, and so on. (Lee, 1996).

The availability of vegetable oil is limited to the physicochemical changes that occur during extraction and storage. Typically, the oxidation process in vegetable oil varies according to the extraction method used and storage time, and such variations can lead to big problems in food hygiene as it can generate harmful substances (Song et al., 2003). Sancho oil is being extracted using traditional methods, and each extraction method is different for each region. Sancho oil has been used to limit food functional materials that can cause health challenges because of severe rancidity.

Crude vegetable oils and fats contain many undesirable materials such as free fatty acids, color pigments, gums, waxes, phosphates, trace metals, pesticide residues, and odoriferous materials, which are required to be removed to produce a stable product with a bland or pleasant taste (Ghazani et al., 2013). Some of the impurities, such as seed fragments and meal fines, are oil insoluble and thus can be readily removed by filtration. Others, including free fatty acids, hydrocarbons, ketones, tocopherols, glycolipids, phytosterols, phospholipids, proteins, pigments, and resins, are soluble or form stable colloidal suspensions in the oil. Most of these have unfavorable effects on the flavor, odor, appearance, and shelf life of the oil, and therefore have to be removed from the vegetable oils by chemical or physical refining processes (Verleyen et al., 2002). Several chemical and physical refining processes, including degumming, neutralization, bleaching and deodorization, have been designed to remove these materials and to obtain odourless, bland and oxidatively stable oils, which are acceptable to consumers. Soybean and canola oil are marketed after going through the refining process (Farhoosh et al., 2009).

Although oil refining process has been studied for edible oils such as canola oil, soybean oil, there is no research carried-out for sancho oil. This study was performed in order to improve the quality of sancho oil and enhance its availability throughout the purification process.

MATERIALS AND METHODS

1. Materials

The sample used for the study was used to oil extracted from a sancho (Zanthoxylum schinifolium Siebold & Zucc.) tree farm located in Korea. Sancho seed-pods were collected on 5th October, 2013 and then the oil was immediately extracted from them. The extraction of sansho oil was performed by the compression method. After picking the sancho seeds, they were extracted with a extraction machine (Gaebangagan, Oscarelectronic Co., Ltd., Gimhae, Korea). The oil was cooled at room temperature and centrifuged at 2,500 rpm for 5 minutes using a centrifuge. The supernatant was collected and stored at 5℃ and used as a sample.

2. Determination of degumming effect

We added 10㎖ phosphoric acid and acetic acid that concentration each of 0.05 - 0.3% into 100 g of sancho oil, and then the efficiency was measured according to the degumming effect. Degummed sancho oil was analyzed based on the method described below, to obtain the acid value, polyphenol content, antioxidant activity and fatty acid content.

We prepared 5 N H2SO4, 0.01 M potassium antimonyl tartrate, 4% ammonium molybdate, and 1M ascorbic acid by mixing reagents. These reagents (50㎖ of 5 N sulfuric acid, 5㎖ potassium antimonyl tartarate, 15㎖ ammonium molybdate, and 30㎖ ascorbic acid) were mixed and adjusted to a total volume of 100㎖, and we then mixed 5㎖ sancho oil with 0.8㎖ of the mixed reagents. These mixtures were allowed to stand for 30 minutes, and then 2㎖ of 95% EtOH was added to each mixture vortexing again, then the absorbance was measured using 880 ㎚ UV/Vis Spectrophotometer (LibraS22, Biochrom, Cambridge, England). 0.8㎖ KH2PO4 was added into each reagent mixture and kept for 30 minutes in order to examine the standard calibration curve of phosphate. We added 2㎖ of 95% EtOH into the reagent mixtures and vortexed again, and then measured the absorbance using 880㎚ VIS Spectrophotometer. Total phosphorus content was calculated using the calibration curve.

3. Determination of deoxygenation effect

In order to calculate the yield and acid value of oil, we added 1 - 3 N sodium hydroxide (NaOH) into 100 g of sancho oil, and then examined the mixture after the addition of an optimal concentration of NaOH. The mixture of sancho oil and NaOH was reacted in a water bath with temperature of 80℃, and then stirred for 10 min using a glass rod and the sample was further reacted for 30 min. The deoxidized oil was analyzed based on the method described below, to obtain the acid value, polyphenol content, antioxidant activity and fatty acid content.

4. Analysis of polyphenol content in purified sancho oil

After the input of 0.3% Chinese pepper oil, 1㎖ ether was collected for dilution of the sancho oil. Sancho oil was diluted with 1㎖ 95% ethanol, 5㎖ of distilled water and 0.5㎖ 1 N Folin-Ciocalteau (Sigma-Aldrich Co., St. Louis, MO, USA), and then vortexed and reacted for 1 hour under dark condition. The total polyphenol content of the sample was calculated by using tannic acid as standard, and then measured with a 725㎚ Vis Spectrophotometer (Vernier Software and Technology, Beaverton, OR, USA).

5. Analysis of the fatty acid content in purified sancho oil

Analysis of fatty acid (FA) content in refined sancho oil was conducted by slightly modified method of Bae et al. (2011). For the preparation of FAME, the AOAC method (2001) was modified as follows: we weighed 0.5 g of the oil sample accurately in a flask (30㎖) and 5㎖ of 0.5M methanolic sodium hydroxide (Sigma-Aldrich Co., St. Louis, MO, USA) solution was added for the saponification. Reflux condenser (15㎝, in length) was attached to the flask and heated at 140 - 160℃ for 5 min. on a heating mantle. 5㎖ of boron trifluoride-methanol (Sigma-Aldrich Co., St. Louis, MO, USA) was then added from a pipet through a condenser and we continued heating at 140 - 160℃ for 5 min.

The flask was removed from the heating mantle and refluxed, and the solution allowed at room temperature. 5㎖ of n-hexane (Sigma-Aldrich Co., St. Louis, MO, USA) and about 10㎖ of saturated sodium chloride (Sigma-Aldrich Co., St. Louis, MO, USA) solution were added, and then the content was agitated thoroughly. An aliquot of the supernatant hexane layer was transferred into a Pasteur pipette (5 3/4 inch) packed with anhydrous sodium sulfate (about 1 g) to remove water. Following filtration, 0.1㎕ of filtrate was analyzed using gas chromatography (GC).

The purified samples were analyzed using GC (Agilent GC 6890, Agilent Technologies Inc., Santa Clara, CA, USA). Analysis column was used for DV-WAX (60 m × 0.25㎜ id, 0.25㎛). The mobile phase used was a nitrogen gas, and the moving speed was set at 1.3㎖/min. The amount injected was 0.1㎕ and the split ratio was 1 : 60. Temperature settings were as follows: injector 230℃; FID 230℃. The oven temperature was maintained at 160℃ for 5 min, and then programmed to 210℃ at 4℃/min, and maintained for 6 min at 210℃. GC peak areas were integrated with a Chromato integrator (D-2500, Hitachi Ltd., Tokyo, Japan).

The peak areas were normalized using unity response factors. The total amounts of palmitic (C16 : 0), stearic (C18 : 0), oleic (C18 : 1), linoleic (C18 : 2), and linolenic (C18 : 3) acids were calculated as hundredth of a percent. All traces of FA less than 0.1% or a specific FA found in limited amounts in the oil were excluded in this study for the simple comparison.

6. Analysis of antioxidant activity in purified sancho oil

We measured the antioxidant activity of refined oil by using the DPPH method (Kiers et al., 1976). The measurement wavelength of DPPH was 517㎚ in UV/ VIS-spectrophotometer (Uvikon XL, BIO-TEK, Winooski, VT, USA).

7. Statistical analysis.

Change of acid value in sancho oil treat by degumminf and deoxygenation, and polyphenol content, saturated and unsaturated fatty acid content according to the purification process were analyzed by One-way ANOVA using the IBM SPSS statistical package, and significant differences among treatments were tested at the 5% significance level, Duncan's Multiple Range Test (DMRT).

RESULTS

1. Density and crude fatty acids content of unpurified sancho oil

The results showed that the density of sancho oil is 0.903㎏/㎥ (Table 1). In general, the density value of the edible oil in Korea differed from the 0.92 - 0.94㎏/㎥ value (Korea Food Sanitation Act Food Sanitation Act. Act No. 10787). The extracted sancho (Zanthoxylum schinifolium Siebold & Zucc.) oil was 0.906㎏/㎥, similar to other edible oil. Also, crude fatty acid content of sancho oil was 61.8%.

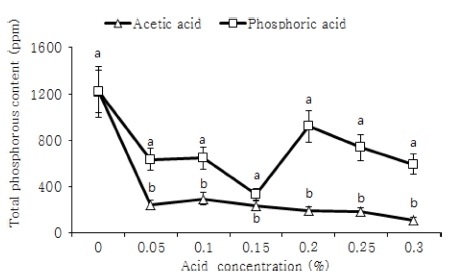

2. Degumming efficiency using phosphoric acid and acetic acid

Degumming efficiency differed depending on the phosphoric acid and acetic acid treatments (Fig. 1). The acetic acid treatment had a better phosphorous removal effect than the phosphoric acid treatment. Degumming efficiency of sancho oil increased depending on the concentration of the two acids treatments. Degumming efficiency using 0.05% acetic acid was about 80% higher compared to the non-treatment. Also, the degumming efficiency of the 0.15% phosphoric acid treatment was dramatically improved. However, the reason for this improvement is unknown. The use of acetic acid showed an efficiency of about double that of phosphoric acid.

Phosphorus content of sancho oil in accordance with the phosphoric acid and acetic acid treatment.Values are reported as the means of six replicates ± standard deviation, and the alphabetical words in the Figure show the results of the DMRT analysis (p < 0.05).

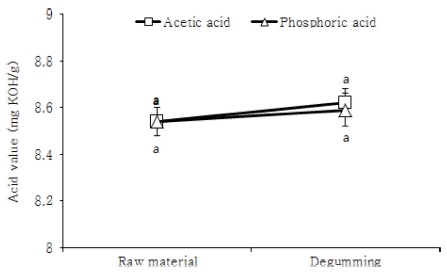

Degumming process was not give to significant change for the acid value of sancho oil. (p-value : 0.392) (Fig. 2). Although mean of acid value was higher acetic acid than phosphoric acid, there was not shown the significant different. (p-value : 0.123) In degumming process, slightly increase of acid value be likely to degumming with only use water (data not shown).

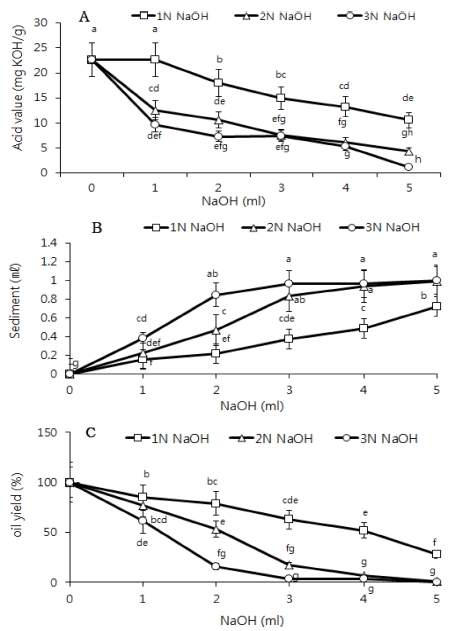

3. Deoxygenation efficiency according to the amount of NaOH

The precipitate amount in sancho oil increased with increase in NaOH concentration (Fig. 3). The formation of precipitates was not significantly influenced by the concentration of NaOH.

Change of the precipitate and acid value in sancho oil treated with different concentrations of NaOH.Values are reported as the means of three replicates ± standard deviation, and the alphabetical words in the Figure show the results of the DMRT analysis (p < 0.05).

Acid value also differed depending on the NaOH concentration, as it decreased with increase in NaOH concentration (Fig. 3A). When treated with 1 N NaOH, acid value of oil somewhat decreased. The amount of precipitate increased rapidly with NaOH treatment (Fig. 3B). The amount of precipitate increased as the concentration of NaOH increased. Oil yield decreased with the amount of NaOH treated (Fig. 3C). Oil yield decreased with increasing NaOH concentration.

4. Polyphenol content change during the purification process

The total polyphenol content was dramatically decreased through the purification process (Fig. 4). Polyphenol content of untreated sancho oil was 667 ppm. Polyphenol content in degummed and deoxidated oil was reduced to 44.5% and 46.4%, respectively. The content of total polyphenol in sancho oil after completing all the purification processes was reduced by approximately 9% compared to the raw material.

5. Antioxidant activity in the purification process

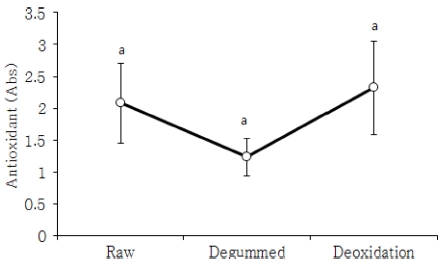

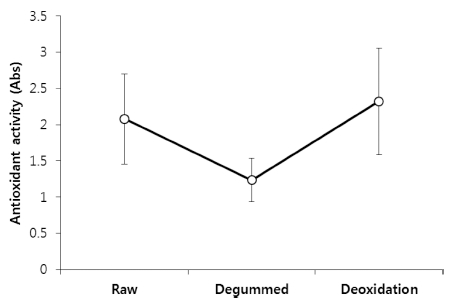

Antioxidant activity of the sancho oil was different for each refining process (Fig. 5). Antioxidant activity was decreased in the degumming process and then increased again in the deoxygenation process.

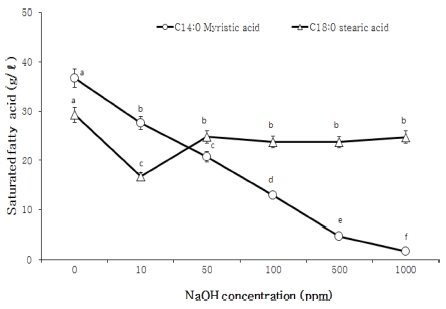

6. Change of fatty acid content according to the NaOH treatment

The saturated fatty acid content varied according to the concentration of NaOH (Fig. 6). Myristic acid (C14 : 0) and stearic acid (C18 : 0), which are saturated fatty acids contained in the sancho oil, decreased with increased concentration of NaOH. The amount of stearic acid (C18 : 0) was less than that of myristic acid (C14 : 0) in the 50 ppm NaOH concentration.

The content of saturated fatty acid in sancho oil in accordance with the NaOH treatment.Values are reported as the means of three replicates±standard deviation, and the alphabetical words in the Figure show the results of the DMRT analysis (p < 0.05).

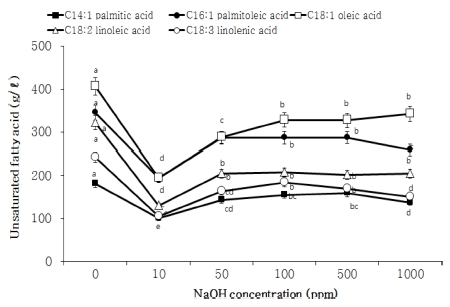

For the unsaturated fatty acids, the contents of palmitic acid (C14 : 1) and palmitoleic acid (C16 : 1) slightly decreased with increase in the concentration of NaOH used in the deoxygenation process (Fig. 7). However, the contents of unsaturated fatty acids were not significantly influenced by the concentration of NaOH. The contents of unsaturated fatty acids were much decreased after treatment with 10 ppm NaOH concentration. The palmitic acid content of 100 g/ℓ decreased by 44.6% compared to the control.

The content of the unsaturated fatty acids in sancho oil in accordance with the NaOH treatment.Values are reported as the mean of three replicates ± standard deviation, and the alphabetical words in the Figure show the results of the DMRT analysis (p < 0.05).

In 10 ppm NaOH concentration, palmitoleic acid content of 195 g/ℓ was reduced by 43.5% compared to the control. Oleic acid (C18 : 1), linoleic acid (C18 : 2), and linolenic acid (C18 : 3) showed the greatest decrease rate when treated with 10 ppm NaOH concentration. The contents of oleic acid, linoleic acid and linolenic acid decreased by 52.5%, 59.4% and 56.8%, respectively, whereas comparatively, the contents of palmitic acid (C14 : 1) and palmitoleic acid (C16 : 1) decreased by about 10%. However, the content of oleic acid (C18 : 1) experienced an increase even though it was lower compared to that of the control experiment (p value < 0.05).

7. Change of fatty acid content based on the purification process

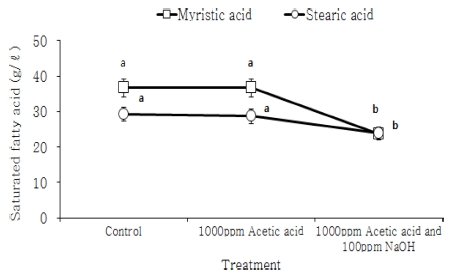

The content of saturated fatty acids in the sancho oil reduced while passing through the purification process (Fig. 8). The content of myristic acid (C14 : 0) was higher than that of stearic acid (C18 : 0) in the degumming process, but it was similar in the deoxidation process. The degree of reduction varied according to the type of saturated fatty acids (Fig. 8A). The decline of myristic acid (C14 : 0) content was twice more than that of stearic acid (C18 : 0). Therefore, the NaOH used in the deoxygenation step was more effective in the removal of lower fatty acids than the higher fatty acids.

Changes in the saturated fatty acids contents in sancho oil according to the purification process.Values are reported as the mean of three replicates±standard deviation. and the alphabetical words in the Figure show the results of the DMRT analysis (p< 0.05).

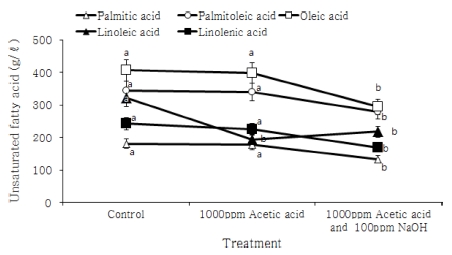

The content of the unsaturated fatty acids; palmitic acid (C14 : 1) and palmitoleic acid (C16 : 1) decreased depending on the purification process, with the reduction rate similar to that of the saturated fatty acids in the degumming process (Fig. 8B).

The content of Palmitic acid (C14 : 1) was reduced by about 2.4% in the degumming process, and about 23.7% in the deoxidation process. The Palmitoleic acid (C16 : 1) content was also reduced by 1.7% in the degumming process, and 17% in the deoxidation process. This decline in the degumming process was 10 times higher than in the deoxidation process.

The contents of major unsaturated fatty acids such as oleic acid (C18 : 1) and linolenic acid (C18 : 3) decreased in the degumming process (Fig. 9). Also, the contents of oleic acid (C18 : 1) and linolenic acid (C18 : 3) decreased in the degumming process.

Changes in the unsaturated fatty acids contents in sancho oil according to the purification process.Values are reported as the mean of three replicates±standard deviation. and the alphabetical words in the Figure show the results of the DMRT analysis (p < 0.05).

When treated with NaOH, the decomposition rate of high fatty acids in sancho oil was greater than that of low fatty acids. The linoleic acid (C18 : 2) content showed a large reduction of about 39.3% in the degumming process, whereas its content in the deoxidation process was increased by about 7%. This means that the unsaturated fatty acid, linoleic acid (C18 : 2) is easily decomposed by an acid. In addition, the increase in the contents of linolenic acid (C18 : 3) and linoleic acid (C18 : 2) in the NaOH treatment appears to be due to decomposition.

RESULTS AND DISCUSSION

The density of sancho oil was similar to that of sunflower oil (0.916 - 0.923㎏/㎥), soybean oil (0.917 - 0.924㎏/㎥) and linseed oil (0.925 - 0.932㎏/㎥) (Güner et al., 2006).

The crude fat content was 50% of sesame seed oil (Kang et al., 2000), 45.5% of rapeseed oil (Kang et al., 1980), 46.5% of pumpkin seed oil (Kim et al., 1978) and 22.1% of sunflower seeds (Choi et al., 1979).

Alkali agents such as potassium hydroxide and sodium hydroxide neutralized free fatty acids, and soap stock was removed from the neutralized reactant. In this study, sodium hydroxide affected color and fatty acid content. Chung (2000) reported that sodium hydroxide treatment decreased color and fatty acid content of tea seed oil. Normally, sodium hydroxide solutions containing 17 - 18 Be (14.4%) and 12 Be (8%) are used as alkali agents for the purification of soybean oil, seed gathering oil and palm oil, respectively (Gunstone et al., 1982).

The common oilseeds such as soybean, cottonseed, sunflower and rapeseed are rich sources of phospholipids (Indira et al., 2000; Willem and Mabel, 2008). Phospholipids pose many problems for the storage and processing of crude oil and are removed from oil during refining by a process known as degumming (Brekke, 1980).

Degumming is highly dependent on the concentration of acid in the treatment. In this study, the influence of acetic acid was higher than that of phosphoric acid. Therefore the acid type, concentration and reaction temperature are important factors to be considered in the acid degumming process. However, the influence of these factors vary for each type of oil. Pan et al. (2000) reported that the effect of degumming agent at 8% concentration and a temperature of 70℃ presented the least efficient treatment in the case of phosphoric acid, but more effective for citric acid and for acid mixture. This means that the degumming efficiency depends on the type of oil.

We found out that, neutralization significantly reduced a and b color values. There are many undesirable compounds like free fatty acids, phospholipids, pigments and waxes in the degummed oil that might promote oxidation and result to undesirable color and odor in the final product. Thus, neutralization is a step that neutralizes free fatty acids and removes undesirable components in the degummed oil (Wei et al., 2015).

The total polyphenol content was dramatically decreased throughout the purification process. This is due to the unstable nature of phenolic compounds during the oil refining process when heat treatment is applied. Degumming, bleaching, and deodorization were effective in reducing total polyphenol in kenafseed oil during the refining process. Chew et al. (2016) reported that refining of kenaf seed oil led to a decrease in 64.5% of the total polyphenol contents.

Antioxidant activity was decreased during the degumming process, but was increased in the deoxygenation process. The reason for the low antioxidant activity is presumably because the content of the antioxidant active substance was low due to degumming. Yosida et al. (1993) reported that antioxidant activity of palm oil was reduced most especially after bleaching and degumming probably due to the oxidation of tocopherols into tocoquinones.

The content of the major unsaturated fatty acids i.e. oleic acid (C18 : 1) and linolenic acid (C18 : 3) decreased with the progress of the degumming process. Vegetable oils contain substantial amounts of linolenic acid (C18 : 3), which is responsible for the development of an off-flavour problem known as flavour reversion (Fennema, 1996). Similar results were found by Abitogun et al. (2008) and Shahidi (2005). Although the phosphoric acid used for degumming did not have direct reaction with free fatty acid, some of the free fatty acid was lost in the degumming stage of the refining process. These results obtained were different from the findings of Thomopoulos and Thomopoulos and Tzía (1993) who reported that the hydration conditions caused an increase in acidity of the degummed oil and this increase could be attributed to the partial hydrolysis of the triglycerides molecules which were enhanced by longer contact time in the hydration process.

Degumming and deoxidation process reduce the content of fatty acid and antioxidant activity but it is indispensable to improve the quality of sancho oil. The results of this study may contribute to the storage and distribution of the oil. This study will contribute significantly to the industrialization of sancho oil.

ACKNOWLEDGEMENTS

This work was supported by a grant(S111616L170110) from the Forest Science and Technology Project, Republic of Korea Forest Service.

References

- Abitogun, A, Jide, A, Arawande, J, Alademeyin, O, Omosheyin, A, Effects of phosphoric acid on physicochemical parameters of soyabean oil, The Internet Journal of Nutrition and Wellness, (2008), 8, p1-5.

- Anderson, D, Antioxidant defences against reactive oxygen species causing genetic and other damage, Mutation Research, (1999), 350, p103-108.

- Association of Official Analytical Chemists(AOAC), Official methods of analysis, (2001), Association of Official Analytical Chemists, Washington, DC, USA.

-

Bae, SM, Jin, YM, Jeong, EH, Kim, MB, Shin, HY, Ro, CW, Lee, SC, Studies on proximate composition, fatty acids and volatile compounds of Zanthoxylum schinifolium fruit according to harvesting time, Korean Journal Medicinal Crop Science, (2011), 19, p1-8.

[https://doi.org/10.7783/kjmcs.2011.19.1.001]

- Erickson, DR, Brekke, OL, Erickson, DR, , Oil degumming and soybean lecithin, Handbook of soy oil processing, (1980), American Soybean Association, St. Louis. Mo, American Oil Chemists’ Society, Champaign. IL, USA, p71-78.

-

Chew, SC, Tan, CP, Long, K, Nyam, KL, Effect of chemical refining on the quality of kenaf(Hibiscus cannabinus) seed oil, Industrial Crops and Products, (2016), 89, p59-65.

[https://doi.org/10.1016/j.indcrop.2016.05.002]

- Choi, KY, Ko, YS, Studies on the constituents of Korean edible oils and fats: Part 3. studies on the oil soluble constituents of sunflower seeds, Korean Journal of Nutrition, (1979), 12, p75-85.

- Chung, YM, Utilization of tea seeds for food. Master Thesis, (2000), Chonnam National University, p4-92.

-

Farhoosh, R, Einafshar, S, Sharayei, P, The effect of commercial refining steps on the rancidity measures of soybean and canola oils, Food Chemistry, (2009), 115, p933-938.

[https://doi.org/10.1016/j.foodchem.2009.01.035]

- Fennema, OR, Food chemistry, (1996), 3rd ed, Marcel Dekker, New York. NY, USA, p225-321.

-

Ghazani, SM, Garcia-Llatas, G, Marangoni, AG, Minor constituents in canola oil processed by traditional and minimal refining methods, Journal of the American Oil Chemists Society, (2013), 90, p743-756.

[https://doi.org/10.1007/s11746-013-2215-2]

- G?ner, FS, Ya?ci, Y, Erciyes, AT, Polymers from triglyceride oils, Progress in Polymer Science, (2006), 31, p633-670.

- Gunstone, FD, Norris, FA, Lipids in foods Chemistry, biochemistry and technology, (1982), Pergamon Press, Oxford, England, p108-109.

- Gutteridge, JMC, Halliwell, B, Antioxidants in nutrition, health, and disease, (1994), Oxford University Press, London, England, p1-62.

-

Indira, TN, Hemavathy, J, Khatoon, S, Gopala Krisna, AG, Bhattacharya, S, Water degumming of rice bran oil A response surface approach, Journal of Food Engineering, (2000), 43, p83-90.

[https://doi.org/10.1016/s0260-8774(99)00135-1]

- Kang, MH, Ryu, SN, Bang, JK, Kang, CH, Kim, DH, Lee, BH, Physicochemical properties of introduced and domestic sesame seeds, Journal of the Korean Society of Food Science and Nutrition, (2000), 29, p188-192.

- Kang, S, Lee, KH, Shin, HS, Studies on the lipid components of Korean rapeseed oil, Korean Journal of Food Science and Technology, (1980), 12, p115-121.

-

Kiers, CT, De Boer, JL, Olthof, R, Spek, AL, The crystal structure of a 2,2-diphenyl-1-picrylhydrazyl(DPPH) modification, Acta Crystallographica Section B, (1976), 32, p2297-2305.

[https://doi.org/10.1107/s0567740876007632]

- Kim, JM, Yoon, HK, Analytical studies on the fatty acids and amino acids composition of Pinus koraiensis seed, Reports of Agricultural Research and Technology Chungnam University, (1975), 2, p469-474.

- Kim, JP, Lee, YJ, Nam-Kung, S, Studies on the composition of fatty acid and protein in pumpkin seeds, Korean Journal of Food Science and Technology, (1978), 10, p83-87.

- Lee, SJ, Korean folk medicine monographs, (1996), Publishing Center of Seoul National University, Seoul, Korea, p88.

-

Pan, LG, Campana, A, Toms, MC, An, MC, A kinetic study of phospholipid extraction by degumming process in sunflower seed Oil, Journal of the American Oil Chemists' Society, (2000), 77, p1273-1277.

[https://doi.org/10.1007/s11746-000-0200-8]

- Park, YH, Park, JW, Kim, TS, Choi, SA, Chun, SJ, Triglyceride compositions of peach kernel and apricot kernel oil, Journal of the Korean Society of Agricultural Chemistry and Biotechnology, (1984), 27, p278-284.

- Pyo, YH, Kim, IS, Ahn, MS, Study on the oxidative stability of Korean evening primrose oil, Journal of Korean Society of Food Science, (1989), 5, p27-34.

-

Shahidi, F, Shahidi, F, Quality assurance of fats and oils, Bailey’s Industrial Oil and Fat Products, (2005), John Wiley and Sons, Hoboken. NJ, USA, p120-124.

[https://doi.org/10.1002/047167849x.bio072]

- Song, J, Bang, JK, Park, HW, Park, CB, Seong, NS, Oxidative stability and fatty acid composition during storage of chufa oil, Journal of the Korean Society of International Agriculture, (2003), 15, p31-37.

-

Thomopoulos, CD, Tzia, C, The effect of degumming by hydration on the purification of high acidity solvent extracted olive oil, Grasas y Aceites, (1993), 44, p259-262.

[https://doi.org/10.3989/gya.1993.v44.i4-5.1076]

-

van Nieuwenhuyzen, W, Tomas, MC, Update on vegetable lecithin and phospholipid technologies, European Journal of Lipid Science and Technology, (2008), 110, p472-486.

[https://doi.org/10.1002/ejlt.200800041]

-

Verleyen, T, Sosinska, U, Ioannidou, S, Verhe, R, Dewettinck, K, Huyghebaert, A, Greyt, WD, Influence of the vegetable oil refining process on free and esterified sterols, Journal of the American Oil Chemists' Society, (2002), 79, p947-953.

[https://doi.org/10.1007/s11746-002-0585-4]

-

Wei, J, Chen, L, Qiu, X, Hu, W, Sun, H, Chen, X, Bai, Y, Gu, X, Wang, C, Chen, H, Hu, R, Zhang, H, Shen, G, Optimizing refining temperatures to reduce the loss of essential fatty acids and bioactive compounds in tea seed oil, Food and Bioproducts Processing, (2015), 94, p136-146.

[https://doi.org/10.1016/j.fbp.2015.02.003]

-

Yoshida, H, Kajimoto, G, Emura, S, Antioxidant effects of d-tocopherols at different concentrations in oils during microwave heating, Journal of American Oil Chemists' Society, (1993), 70, p989-995.

[https://doi.org/10.1007/bf02543025]

- Youn, KS, Hong, JH, Choi, YH, Optimization for extraction of Sancho(Zanthoxylum schinifolium) extraction using supercritical carbon dioxide, Food Engineering Progress, (2006), 10, p207-213.